Technifex remixes the formula to highlight solutions capabilities

by Gene Jeffers

“The pandemic was, ironically, a once in a lifetime opportunity. The entire world stopped,” says Technifex owner and CEO Monty Lunde. “We couldn’t waste the time since the pause gave us a chance to reinvent and improve what we do, how we do it, and why we do it. As challenging as it was, it has been two years well spent growing Technifex into a more efficient, more capable full-service enterprise. We are now better able to create and deliver exceptional immersive effects and technical solutions to multiple markets around the world.”

In early 2020, Lunde was just beginning to reorganize the firm following the retirement of longtime partner Rock Hall when the pandemic struck. “We were fortunate; we had an experienced and passionate staff,” Lunde notes. “Within a few weeks of the COVID onset, everything changed.”

Thanks to in-house reserves and government Covid relief programs, Technifex kept most of the staff on board. Within weeks, with new health protocols in place, their people were back in the shop completing remaining contracts. But what next?

“We asked ourselves, ‘What can we do during this time to make Technifex a better company? To make Technifex a better place to work, improve our efficiency and be ready when the world reopens?’” Lunde laughs and says the initial project was to remodel the lunchroom. “It sounds crazy, I know, but it was a start. And now we have a fantastic gathering place for the staff.” That first step opened the team up to other possibilities.

“We went on to ask ourselves, ‘What do we do best? Where and how do we deliver the most value for our clients?’” That answer came quickly, Lunde says. “Technifex has the passion, the expertise, the R&D and production facilities needed to create inspiring and impactful immersive environments and unique technical solutions for our clients.”

Known worldwide for their innovative products and systems — FauxFire®, FlowScreen®, Dragon’s Breath Heat Blaster to name a few — Technifex spent decades satisfying client demands for more realism, more flexibility, reliability and impact. Could they now take their offer to the next level? (Yes, they could.)

Improving Technifex’s 42,000 square feet of facilities, its organization and equipment became the focus. Every aspect of the company was addressed with the objective of improving service by making research, development and production more capable and efficient. A far larger and more powerful water jet machine replaced an older one. Water-effects test equipment is now consolidated into a single-focus Aqua Lab with increased capabilities. The 20,000-gallon water effects test pool behind the building is augmented and reequipped. Steam effects test equipment is upgraded and integrated. Research and fabrication areas are reorganized for improved workflow. Two large and dedicated demonstration areas now showcase services and products. “Every square foot of our two buildings was re-examined and upgraded,” says Lunde.

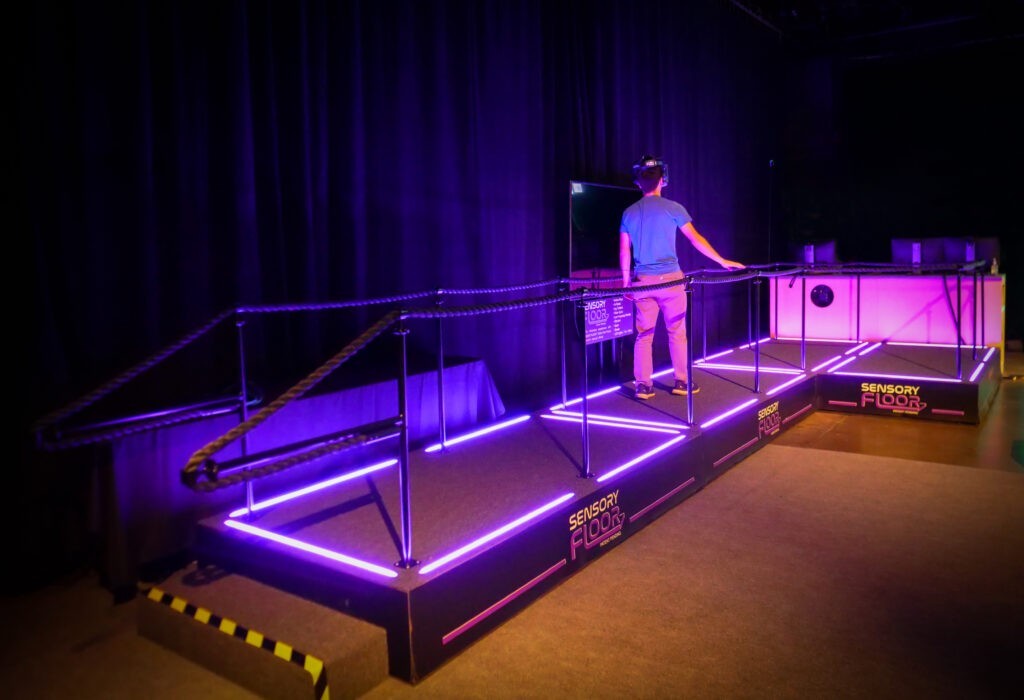

Technifex’s existing products are now refined with an eye to quality, cost and deliverability. Derivative products and new applications are in production to meet future demands. 3D printing is being used to improve performance and dramatically lower production costs of their Variable Pattern Nozzle. A modular and scalable product, their Sensory Floor™, with built-in effects — wind, scent, leg ticklers, transducers, LEDs, pneumatic motion — is ready for delivery.

Meanwhile, Technifex staff are realigned to better fit with client service and product development needs. John Polk, promoted to SVP, Executive Producer, now works directly with the firm’s top themed entertainment clientele. Celebrating 28 years at Technifex, Joe Ortiz, as SVP of Creative Technologies, coordinates the team of in-house and external technologists. Stepping into Ortiz’s past role, Maurice Aboulache as VP of Engineering oversees the in-house team of engineers developing advanced effects, show action equipment and control solutions for immersive environments. Other promotions include Gabriel Wilson to Senior Project Manager and Bill Clare to Project Manager. “All of these changes celebrate our people’s strengths and are designed to ensure the best possible working relationships with our clients,” says Lunde.

Joining Technifex and Technifex Products, a new company, Technifex XR, was formed during COVID and now provides solutions for first responder and military immersive training environments. Industry veteran Ian MacVittie runs that company as Executive Vice President.

Leading the industry for 38 years, Technifex once again has demonstrated its ability to adapt and evolve, powered by a dedicated team, entrepreneurial company culture and keen awareness of market conditions. “Bring us your impossible ideas,” Lunde challenges clients, confident in this new Technifex. “We have an unmatched depth of experience, know-how, facilities and processes that allow us to create amazing solutions for our clients.”

For more information, www.Technifex.com, email [email protected] or call +1 661-294-3800 • • •